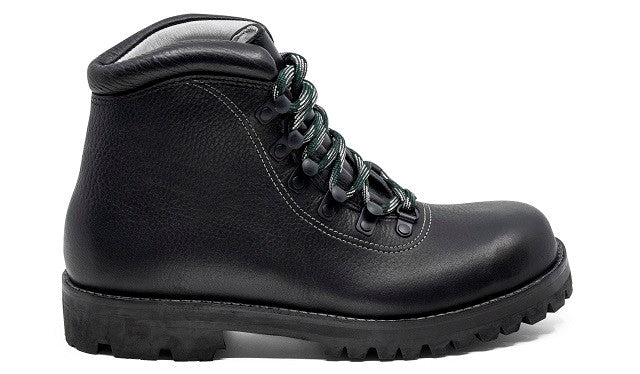

Our Signature Design

One piece leather upper, with a single seam on the instep.

Value

In a world where product cycles have grown shorter and shorter, Limmer Boots are known for their extraordinary longevity and value. By the time you send your boots in for a repair, they will have already become the least expensive pair of boots you have ever purchased.

Philosophy & Dedication

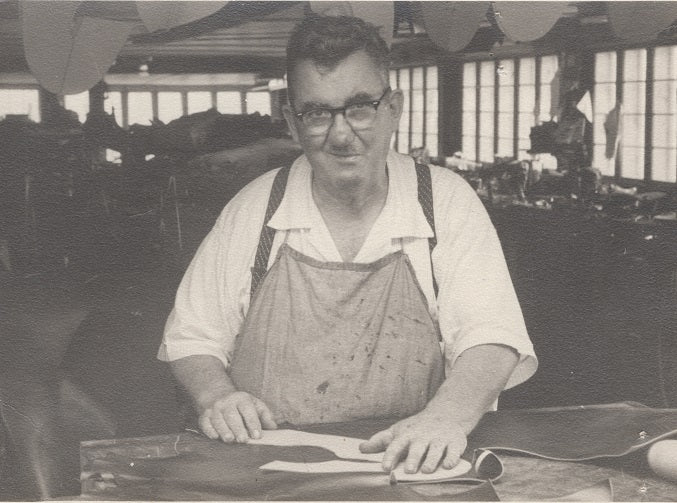

Philosophy - The design and philosophy behind our boots began in 1919 with Peter Limmer, Sr. In 1921, he achieved his master status in bootmaking and began working in Vachendorf, a small village in the Bavarian Alps. The superb quality of his work spread quickly and in 1925, he moved his family to the United States.

Dedication - Over the past 100 years, Limmer has stayed true to the quality and standards that Peter Limmer, Sr. employed. This unique dedication to craft has been appreciated by our customers and has given the boots legendary status in hiking circles, where the punishment of continuous use has repeatedly demonstrated the unsurpassable quality of Limmer.

Dependability & Consistency

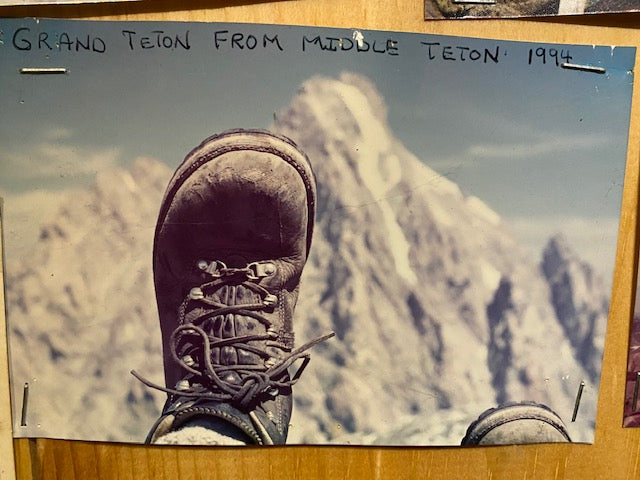

Dependability - Limmer Boots have been used on every type of terrain, including on the slopes of Mount Everest, but part of unique design remains in the boot's crossover quality. Our boots combine the flexibility of a hiking boot, ruggedness to support heavily loaded packs over rocky terrain, and the torsional rigidity to be lightly used with crampons.

Consistency - There have been few design changes over the past 100 years. Where technological advances in materials have made it possible to improve the quality and performance of the boots, those changes have been incorporated. Pure change, however, has never been embraced for its own sake. The clean, exquisite simplicity of its design has never been abandoned, a single piece of leather with a short seam at the instep and a seamless heel remain our trademark.

Design & Materials

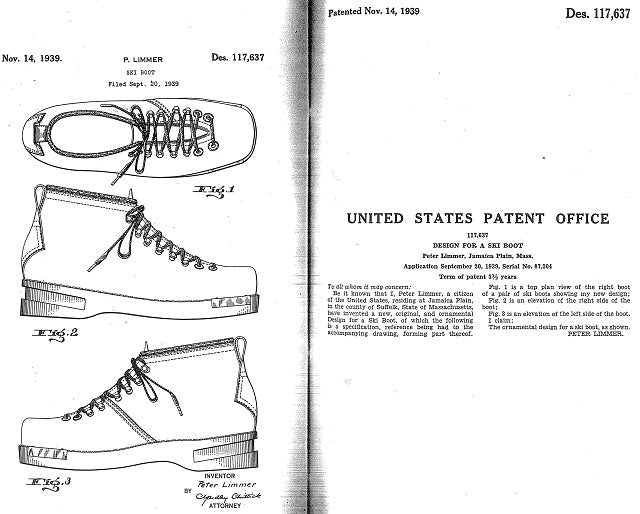

Design in service of function: No element is more important in bootmaking than its design. Design components are in continual service to function, which in the case of mountaineering, dictates the highest degree of reliability and comfort. The finest materials used improperly will not produce a quality boot. For a company to distinguish itself, a delicate balance must be struck between cost, function and weight. Obviously, there is a direct relationship between weight and function. It is Limmer's unique role to maintain the highest functional standards at every weight while producing an uncompromising product at a price just below the top shelf on which it sits. See Peter Limmer, Sr.'s design and patent for the first US Ski Boot.

Ergonomics

Form follows function: There is nothing accidental in the design and construction of a Limmer Boot. Every aspect of the boot has been planned with the goal of producing the most ergonomic boot possible. An ergonomically constructed design is one that applies a series of logically constructed rules to the actual demands of the body. For Limmer Boots, ergonomics means fit, designed specifically for the comfort of the human body. As always, they put the longevity of form and function over the fleeting whim of style.

The Limmer Signature Upper

The Limmer signature: The use of a single piece of leather with a single, short seam in the instep and a seamless interior and exterior heel produces incomparable comfort and longevity. It is the Limmer signature. The outside piece of leather is a full, top-grain, or nubuck chosen for greatest durability and resistance to weather. In converting to leather, it has been subjected to a tanning process that makes it pliable and soft with superb resistance to abrasion.

Signature of quality: The choice of constructing the outer upper with a single leather piece is more expensive because fewer pieces can be cut from each hide, but the reason, as with all Limmer® decisions, has a practical basis illustrated by the following.

The leather upper as outer skin: The extended use of leather will cause it to yield. With boot wear, the heat, pressure and moisture produced causes the cowhide leather to literally mold itself to the foot. The wearer of a Limmer Boot can think of the leather upper as their own tough outer skin which, over time, will adapt itself to the wearer's individual musculature.

The single seam: The Limmer single piece pattern strategically locates the single seam at the concave curve of the arch. The location of this seam assures the shortest length for the least number of stitches that can either tear out or leak.

Protecting the single seam: Locating the seam on a concave surface, as opposed to the convex surface at the back of the foot, affords it greater protection from wear.

Downside of a back seam: The use of a back seam, coupled with a backstrap, produces a rigid, potentially uncomfortable fit that creates discomfort for the wearer in the area of the Achilles tendon especially when descending.

Back seams are not ergonomic: Back seams have a tendency to produce a ridge in their construction which translates to blisters on the wearer's heel. Back seams are a perfect example of a design that is not ergonomic.

Molded construction: Eliminating the back seam allows for a molded construction throughout the boot's heel pocket. This combined with ergonomically designed ankle heel padding provides for maximum comfort under the most strenuous usage.

Specific components of the Upper

Stitching: Limmer Boots utilizes two rows of stitches just outside the lacing fixtures. This prevents the leather from stretching out and altering the fit. Tongue: Limmer's design integrates an open cell foam padded tongue with the outer bellows. This provides protection over the instep. The moderate padding has sufficient bellows to facilitate ease of entry and, at the same time, guarantee a water-proof construction. Inner Lining: Made from fine quality leather, this lining, coupled with the leather upper, allows Limmer boots to be characterized as "all leather" boots. Lacing Fixtures: Made from anodized steel, they are waterproof and rust resistant. Scree Collar: Soft leather with open cell foam padding designed to hinder pebbles or bits of matter from entering the boot. A properly constructed interface from the top of the boot to the bottom of the heel is the wearer's final guarantee of comfort.

Support System

Designing Support: The Limmer support system has been designed for the support and protection of the arch, ankle, toe and heel. Ankle Paddings: Open cell foam padding provides ankle bone protection while it molds itself into an inverted contour of the heel around the vulnerable area of the Achilles tendon. The Heel Counter wraps around the back of the boot and is super burly. This contains reinforced leather fiber to protect the foot when the side of the boot is impacted. It laterally stabilizes the heel within the boot. Side Supports: These provide needed support and impact protection for both sides of the foot especially in the 'waist' (that area just behind the ball of the foot down to the heel) and arch areas. The Toe Box: This contains reinforced fiber. It helps the area maintain a proper shape while providing protection for the toes. The Shank: This area has a multi-thickness, flexible, full length nylon construction designed to take the boot through countless seasons of use. Thinned at those points requiring additional flexibility, it allows for a natural flex pattern to develop in the sole while providing support and protection for load bearing over rough terrain. In 25 years of repairing boots at Peter Limmer & Sons, Ken Smith has only seen 4 broken shanks, and each of those were extreme cases.

The Midsole & Outersole

Midsole Construction: Sandwiched between the inner and outer soles, this area is composed of layers with varying thicknesses. In conjunction with the nylon shank, one or two layers (depending on the model), provide different degrees of flexibility, support and protection from weather and other elements. Outersole Construction: The yellow label on a Vibram Lug Sole is your assurance the materials are the most abrasion resistant compound available. Limmer uses this sole to ensure the toughest possible bottom. Lug pattern and thickness vary according to model, but our use of this brand is part of a continual commitment to quality.

Leather Insole

Current Limmer boot models feature a leather insole, 3.5 to 4.0mm in thickness. Rather than use a more commonly practiced technique combining a 'slip sole' with half the leather thickness backed by plastic, Limmer feels it cannot promote its models as all leather construction without using a substantial piece of leather in this area. However, as with all decisions about the Limmer® design, there are numerous practical and ergonomic reasons for their choice. Leather fit: Unlike any other substance, leather has a quality of molding itself to your foot. Derived from the skin of an animal it can become a wearer's second skin. Leather is unique: Nothing duplicates the ability of leather to sculpt itself to your foot. Further, it continues to improve over time, providing a singular fit and feel. Leather breathes: Because leather is derived from a natural source, it allows a foot to breathe. This is an especially important feature in a leather upper. When the foot is allowed to breathe, moisture and its negative effects, including increased odor, do not build up in the boot. Leather is more effective: The quality of breathability also means using leather ensures the level of effectiveness achieved from every layer of socks will be that much higher. Limmer's commitment to leather: Limmer sees their commitment to single piece, all-leather uppers to be indicative of the uncompromising dedication to quality that characterizes their entire product.

The Norwegian Welt

Understanding Welts:There are a number of ways to attach the upper part of a boot to its sole, but the best of these is the Norwegian Welt or double stitch. Once the superiority of this method is under-stood, it explains why Limmer® employs it in boots intended for the sort of rigorous challenge engendered by load bearing treks over rough terrain. Constructing the Norwegian Welt: The leather upper is attached to the all-leather insole with a horizontal row of stitches after having been stretched and molded over a last. The nylon shank is fitted to the insole and then the bottom edge of the upper is turned outward forming a 'welt'. This is stitched horizontally to the insole and, then, vertically to the layers of the midsole. In Norwegian Welt construction, the upper and the welt are one and the same piece. Both simpler and stronger, this construction also tends to provide greater waterproofing and reparability. The bottom lug sole is attached to the stitched on mid sole with thermally activated adhesive for the greatest degree of bonding available. (see diagram) Identifying Norwegian Welts: You can identify a Norwegian Welt construction by the two rows of stitching around the base of the boot which sits on a 'shelf of about 3.0 to 4.0 mm in width. This method adds some extra weight to the boot, but it also serves as a `bumper' which protects the boot from side impact. It provides a wider more stable platform for the foot to rest on which increases torsional rigidity. It also facilitates reparability. The Norwegian Welt Advantage: Whatever additional weight is produced by this construction, it is more than offset by the great strength and protection created. Possessing consistently comfortable and reliable support is a terrific advantage when engaging in strenuous hiking above tree line, moving from rock to rock, carrying a heavy pack or just hiking a long distance. Flexible construction: Limmer boot models were designed with a flexible construction and are, therefore, not intended for technical climbing. Rather, they are designed for the widest number of uses from all kinds of trails to use with flexible crampons.